-

Spare parts and repair material

- 3M product catalogue

- Batteries (rechargeable)

- Anemometer/Wind vanes

- Safety and protection

- Storage/ Container

- Automation technology

- Lighting technology

- Bergolin product catalogue

- Brake pads

- Brakes

- Condition monitoring systems

- Rotary encoders

- DEHN product catalogue

- Ice detectors

- Electronics

- Electrohydraulics

- Paints/Varnishes/Coatings

- Springs

- Filters

- Generators

- Gearboxes

- Glass fabrics

- Hydraulic parts

- Cables

- Cartridge guns

- Adhesives and sealants

- Carbon brushes

- Corrosion protection

- Couplings

- Fans

- Mankiewicz ALEXIT® BladeRep

- Measurement technology

- Mita-Teknik

- Motors

- Petzl

- Man and material transport

- Pitch drives

- Platforms for rotor blade repair

- Pumps

- Relays

- Repair services

- Rotor blades

- Rotor blade repair products

- Switch cabinets

- Hoses

- Abrasives

- Slip rings

- Slip ring transmitter

- Lubricants

- Bolts

- Shrink discs

- Sensors

- Servocontroller

- Sherwin Williams - Corrosion protection

- Sika product catalogue

- Fuses

- SUZLON Product Catalog

- Tower repair products

- Uninterruptible power supply (UPS)

- Valves

- Consumables

- Maintenance and Lubrication

- Tools

- Roller bearings

- Accessories OEM

- Kategorie Testbonbon

- About us

- Get in touch

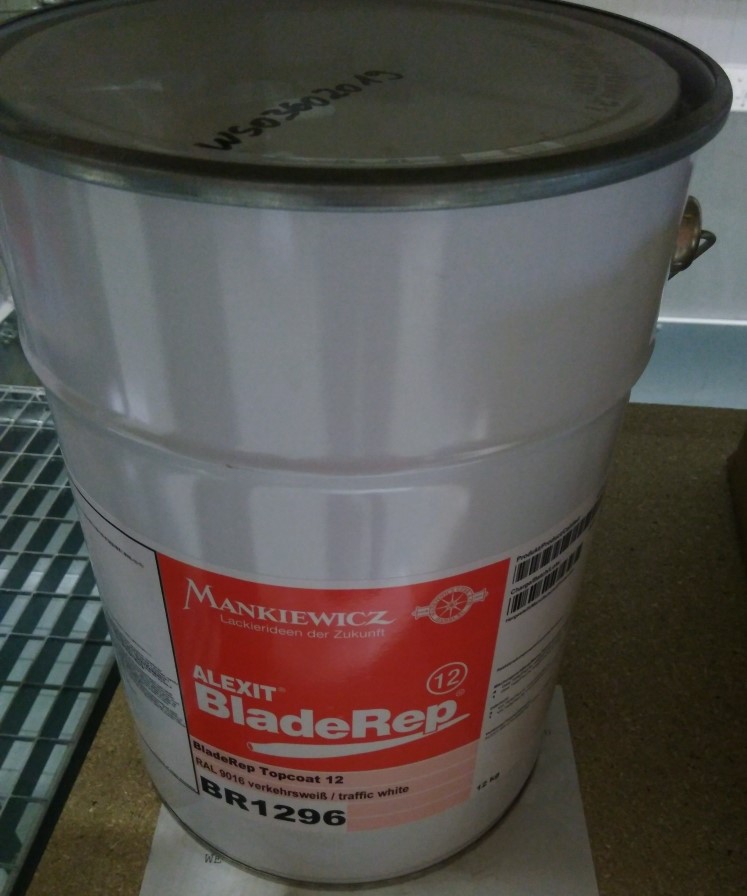

ALEXIT® BladeRep® Topcoat 12

ALEXIT® BladeRep Topcoat 12 is an externally resistant 2-component topcoat based on polyurethane for protection against erosion by rain and particles such as quartz and dust. In addition, ALEXIT® BladeRep Topcoat 12 has a high flexibility and very good chemical resistance.

Specially developed for blade coating where a superior product with chemical, UV and abrasion resistance as well as mechanical resistance is required. This two-component polyurethane topcoat meets or exceeds OEM standards and provides contractors with the ideal product for blade repair.

This high-quality 2-component topcoat on polyurethane basis was developed for the coating of rotor blades. Due to its mechanical and chemical resistances it meets the common requirements of the wind power industry.

| Colours* | RAL 2009 traffic orange, RAL 7035 light grey, RAL 9010 pure white |

| Mixing ratio** | Punch through the lid, empty the entire hardener quantity into master lacquer, add 7% thinner (2 lids) and mix everything thoroughly |

| Pot life | approx. 120 min at 23° C |

| Processing | with foam roller |

| Yield | approx. 2.5 m²/set at 150 µm TSD |

| 2-layer application | 100 to 125 µm per layer at 23° C flash-off time between the layers: 60 min at 23° C |

| Drying time | 3.5 h at 23° C |

| * other colours are available on request ** medium or large containers: for additional information on mixing ratio and yield, see technical data sheet |

| Product | Packaging sizes |

| Basic product: ALEXIT® BladeRep® Topcoat 12 To be used with: |

24 KG/ 12 KG/ 1 KG / 800 gr |

| Hardener: ALEXIT® BladeRep® Hardener 12 |

6 KG/ 3 KG / 220 gr |

| Thinner: ALEXIT® BladeRep® Thinner 12 Medium ALEXIT® BladeRep® Thinner 12 Fast |

10 KG / 1 KG |

Safety Data Sheet ALEXIT® BladeRep® Topcoat 12

Safety Data Sheet ALEXIT® BladeRep® Hardener 12

Safety Data Sheet ALEXIT® BladeRep® Thinner 12 Medium

Safety Data Sheet ALEXIT® BladeRep® Thinner 12 Fast